Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams.

Coal is mostly carbon with variable amounts of other elements;

chiefly hydrogen, sulfur, oxygen and nitrogen.Coal is formed when dead plant matter decays into peat and is converted into coal by the heat and pressure of deep burial over millions of years.

Coal is primarily used as a fuel. With the invention of the steam engine coal consumption increased. As of 2016, coal remains an important fuel as it supplied about a quarter of the world's primary energy and two-fifths of electricity. Some iron and steel making and other industrial processes burn coal.

Gypsum is a soft sulfate mineral composed of calcium sulfate dihydrate, with the chemical formula CaSO4·2H2O.[3] . It is widely mined and is used as a fertilizer and as the main constituent in many forms of plaster, blackboard/sidewalk chalk, and drywall.

The various types of ramming masses ranging from (A) acid (B) Basic (C) Neutral are available.

The lining is termed as acid, basic and neutral depending upon its Chemical nature with the slag formed.

Silica masses are acid ones; alumina is neutral mass while magnetite is basic mass.

Magnesite Ramming Mass is basically burnt magnesite.

Some chemicals are mixed with dead magnesite to form ramming mass.

Mn alloys are mostly used in steelmaking and foundry activities.

There are two families of Mn alloys called ferro-manganese (FeMn) and silico-manganese (SiMn).

Silico-manganese adds additional silicon which is a stronger deoxidizer and which also helps to improve some mechanical properties of steel.

Silico Manganese is an alloy with 65% to 68% manganese, 16% to 21% silicon, and 1.5% to 2% carbon. It is produced by smelting of slag from high-carbon Ferro Manganese

or of Manganese ore with coke and a quartz flux.

Smelting temperatures are high and greater energy is needed to reduce the quartz to silicon.

Ferro Chrome is an alloy of iron and chromium.

Chromium content varies between 50 and 70% depending on the origin of the material.

Its melting point is 1400° approx.

for high carbon and 1620° for low carbon.

As the ferroalloys are primarily used in steel making,

different grades of alloys have been developed to fulfil the varying requirements of the steel industry.

Dolomite is a type of limestone. It is rich in magnesium and calcium carbonate. It also has smaller amounts of several other minerals. It is used for acid neutralization in the chemical industry, in stream restoration projects, and as a soil conditioner. Dolomite is used as a source of magnesia (MgO), a feed additive for livestock, a sintering agent and flux in metal processing, and as an ingredient in the production of glass, bricks, and ceramics.

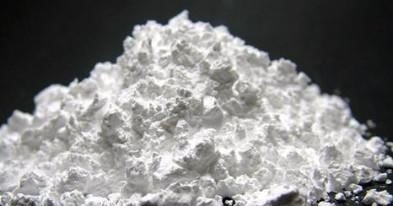

Magnesium oxide (MgO), or magnesia, is a white hygroscopic solid mineral that occurs naturally as periclase and is a source of magnesium (see also oxide).

Magnesium oxide is used extensively in the soil and groundwater remediation,wastewater treatment, drinking water treatment, air emissions treatment, and waste treatment industries for its acid buffering capacity and related effectiveness in stabilizing dissolved heavy metal species. MgO is one of the components in Portland cement in dry process plants.

Sulphur are available in different forms like rolls, granules and lumps. Sulphur is used in manufacturing detergents, plastics etc. These chemicals can also be availed in customized compositions as per client's requirement.

Ground-granulated blast-furnace slag (GGBS or GGBFS) is obtained by quenching molten iron slag (a by-product of iron and steel-making) from a blast furnace in water or steam, to produce a glassy, granular product that is then dried and ground into a fine powder.

GGBS is used to make durable concrete structures in combination with ordinary Portland cement and/or other pozzolanic materials. GBFS may be used without further processing as a construction sand, soil/pavement stabilizing media or grit-blasting material

Cement clinker is a solid material produced in the manufacture of Portland cement as an intermediary product. Clinker occurs as lumps or nodules, usually 3 millimetres (0.12 in) to 25 millimetres (0.98 in) in diameter. It is produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clays during the cement kiln stage.

Clinker consists of various calcium silicates including alite and belite. Tricalcium aluminate and calcium aluminoferrite are other common components. These components are often generated in situ by heating various clays and limestone

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and non-specialty grout.

List of Portland Cement Type 1 as below.

• UltraTech Cement Limited

• Ambuja Cements Limited

• Birla Cement Limited

• JK Cement Limited

• Binani Cement

• ACC Limited

• Jaypee Cement

• Shree Cement Ltd

• Dalmia Cement

• The India Cements Limited